Different Types of Sewing Thread

Different Types of Sewing Thread

Sewing thread

According to the definition given by ASTM, sewing thread is a flexible, small diameter yarn or strand usually treated with a surface coating, lubricant or both, intended to be used to stitch one or more pieces of material or an object to a material. It may be defined as smooth, evenly spun, hard-twisted ply yarn, treated by a special finishing process to make it resistant to stresses in its passage through the eye of a needle and through material involved in seaming and stitching operations.

* American Society for Testing and Materials

Uses of sewing threads :

Sewing threads are used in

- garments

- upholstery

- air-supported fabric structures

- geotextiles

to join different components by forming a seam.

Different Types of Sewing Threads

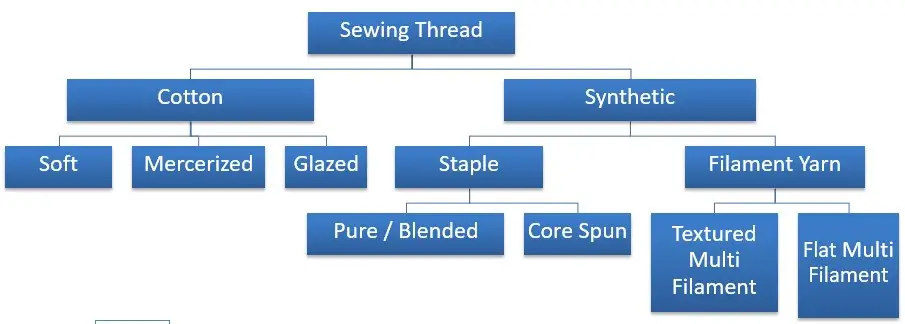

Usually, sewing threads are manufactured from either natural or manmade fibres in either staple or filament form.

Factors for sewing thread classification

1 . Fiber type:

a ) Natural : Linen, Silk, Cotton.

b ) Synthetic : Polyester, Nylon, Aramid.

c ) Blended

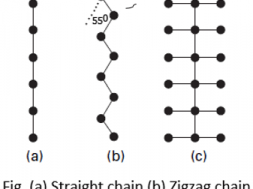

2 . Construction of yarn:

a ) S-twisted

b ) Z-twisted

3 . Thread finishing:

a ) Texturized thread

b ) Core spun thread

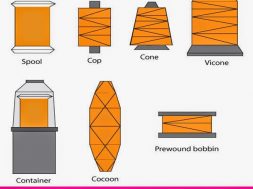

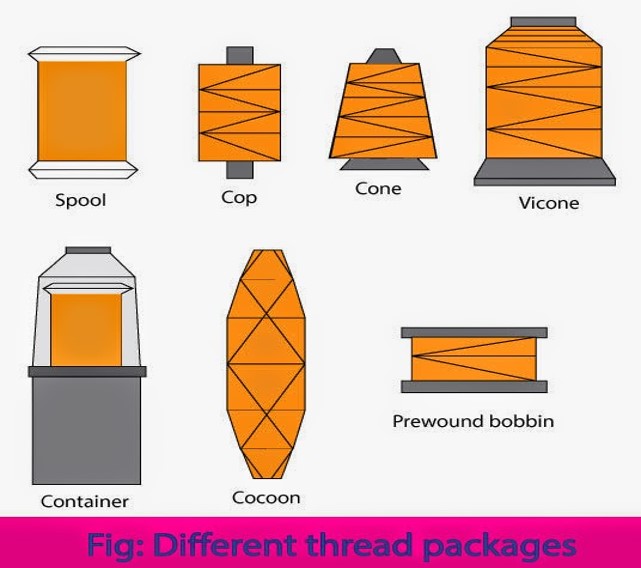

Sewing threads packages

Spool : wood or plastic , double flanged, parallel wound.

Yarn length : Spool thread package contains 100-500 meter thread.

End Uses : Upholstery, Footwear, leather goods manufacturing and in hand sewing operations.

Cop : Cops are small cylindrical flangeless spools, with precision cross wound. Made of paper and plastic. They are two types, small cop (tube) and medium cop(cop).

Yarn length : The length of thread wound ranges from 100-2000 m on small cop and 400-4000 m on cop

End Uses : Kite flying, Upholstery, ready-made garment, tailoring, hosiery, umbrella, and shoe stitching

Cone : This is self-supporting, cross wound conical package. It is easier to withdraw yarn end from a cone than from a cheese and because of this, cone is more widely used.

Yarn length : 1000-25000 m

End uses : readymade garment, tailoring, hosiery, leather stitching, Upholstery, shoe stitching, denim, embroidery, and kite flying.

V-cone or King Spool : V-cones are parallel tubes or low angled cones with an additional base in the form of a raised flange.

Yarn length : 1000-5000 m with length of traverse 6.5-9 cm.

End uses : embroidery, core-spun, and filament threads.

Cocoon : Cocoons are self-supporting i.e. center-less thread package specially designed for the insertion in the shuttle of multi needle quilting and some types of embroidery.

Prewound Bobbin : Prewound bobbins are precision parallel wound thread package designed to replace metal bobbins on a variety of lock stitch machines.

Skein : A very small hank of soft twisted plied thread (around 8 m) of coarse count is parallel wound with the help rotating flyer, which withdraws the thread from the supply package cone.

End uses : embroidery.

Essential Properties required for Sewing Thread

1 . Needle thread must pass freely through the small eye of the needle; consequently they must be uniform, knot-free, non-torque and fault free.

2 . Tensile strength is one of the essential properties of the thread. The strength of the sewing thread must be higher than that of the fabric so that the thread does not rupture during use.

3 . Good abrasion resistance is essential for good sewing performance.

4 . Good resistance to heat is a very important requirement of a sewing thread. Needle heating causes sewing thread breakage, cross-thread, skipped stitches, seam damage and physical damage to the needle.

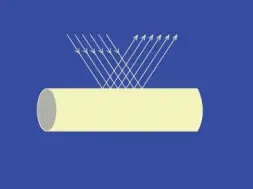

5 . The hairiness of sewing thread also affects the appearance of the seam.

6 . Color fastness is a general requirement for sewing thread. It is important that the selected shade retain its color throughout the life of the garment.

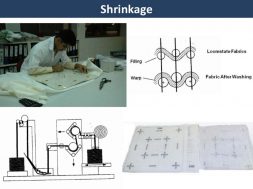

7 . Low shrinkage during washing and ironing is required.

8 . Good luster in the thread improves appearance of the seam.

9 . Threads must be uniformly dyed.

Manufacturing stages of sewing thread

1 . Sorting the initial materials into lots.

2 . Winding threads in spool.

3 . Thread production.

4 . Thread winding ( soft coning).

5 . Dyeing of threads (metal if required).

6 . Drying of threads ( if dyeing is required ).

7 . Thread winding on winder ( hard coning ).

8 . Sorting, marking and packing of finished threads.

(4923)