Yarn Evenness II It’s Classification

Yarn Evenness & It’s Classification

Evenness, Unevenness, regularity, and irregularity are common terms used to describe the degree of uniformity of a textile product. In the textile field, the uniformity of products like the lap, sliver, roving or yam is expressed in terms of evenness or regularity or in terms of unevenness or irregularity.

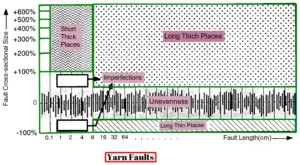

A yarn which is not uniform is said to be irregular or to contain yarn defects or faults. These faults vary in their cross-sectional size and length. Fig. shows a plot of fault cross-sectional size against fault length.

In the above plot, three distinct categories of yarn faults are represented based on their size, length and their frequency of occurrence.

Unevenness or Irregularity

Imperfections

Objectionable yarn faults

Unevenness or Irregularity

The irregularity or unevenness of a yarn is commonly defined as the variation in fineness along its length and more appropriately as the variation in mass per unit length along the yam’. It is expressed as U% or CV%.

The following yam properties are usually subject to variation.

→ Weight per unit length

→ Twists per inch

→ Diameter

→ Strength

Classification of Yarn Irregularity

Generally two types of variation are shown in yarns (especially spun yarns).

1. Random Variation

2. Periodic Variation

Random Variation:

Random variation is a variation that occurs randomly in a textile material without any definite pattern or order is called random variation. This is caused mainly due to the natural variations in the fiber properties.

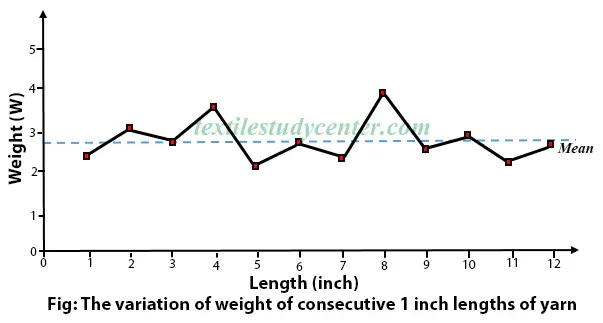

If a yarn was cut into one-inch lengths and the weight of each consecutive length is determined and then the weights are plotted in a graph against the lengths.

When the plotted points are joined to form a graph. It represents an irregularity trace.

A mean line is drawn to indicate the average value of the weight of the one-inch lengths of yarn.

Thus the deviation of each point or value from the mean can be observed. If the deviations from the mean are of a random nature and no definite pattern of variation is visible, as seen in the figure, then the variation is called ‘random variation.

Periodic Variation:

Periodic variation is a variation that occurs at definite length sequences in the textile material.

If a yarn were cut into one-inch lengths and the cross sections of each consecutive length are determined and then the cross-sections are plotted in a graph against adderall generic the lengths. The plots are joined to form a graph as shown and a line indicating the mean value is drawn.

Usually two terminologies ‘wavelength’ and ‘amplitude’ are used to describe the periodic variation.

Figure illustrates these two terms. The wavelength is the distance from one peak of the wave to the next on the same side of the mean line and amplitude is a measure of the size of the deviation from the mean level.

If the deviations from the mean are in a definite sequence, the variation is called ‘periodic variation‘.

Classification of Periodic Variation

Periodic variations may be classified according to their wavelength,using the fiber length as a length unit.

| Periodic Variation | Wavelength |

| Short term variation | 1 to 10 times the fiber length |

| Medium term variation | 10 to 100 times the fiber length |

| Long term variation | 100 to 1000 ( or more) times the fiber length |

The different classes of periodic variation affect the appearance of the woven or knitted fabrics in different ways. The amplitudes of phentermine online short term variations are generally greater than those of the longer term variations. This is because they are usually the result of faulty processing at the last machine and they have had no chance of being reduced in amplitude by drafting and doubling.

Moire effect:

Periodic variations in the range of 1 cm to 50 cm are normally repeated a number of times within the woven or knitted fabric width, which results in the fact periodic modafinil side effects thick places or thin places, will lie near to each other. This produces, in most cases, a “MOIRE EFFECT”. This effect is particularly intensive for the naked eyes if the finished product is observed at a distance of approx. 50 cm to 1m.

Causes of Irregularities

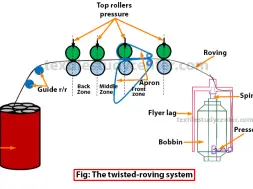

The factors determining the single zone drafting wave irregularity are:

Strictly Random Occurring Faults

- The size of draft

- The count of the input material

- Multiple inputs or doubling

- Roller or drafting zone setting

- The degree of parallelism, length, and fineness of fibers in the input material

Strictly periodic occurring faults

- Eccentricity of roller shaft

- Belt life comes to end

- Bearings out dated

- Apron faults

- Rubber cots faults

- Waste between gear meshing

- 12. Damaged Gear teeth

(3466)