Effective Length of Cotton Fiber

Effective Length (EL):

The effective length is the upper quartile of the fiber length distribution obtained by ignoring short fibers whose length is below half the effective length.

Significance of Effective Length-

The term ‘effective’ is used because it is to this length value that many machinery settings are related, in particular, the distances between the nips of successive pairs of drafting rollers.

The effective length correlates well with the classer’s staple length and hence provide the measurement of the staple of cotton.

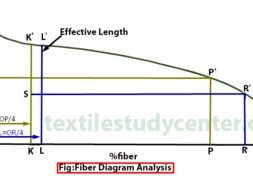

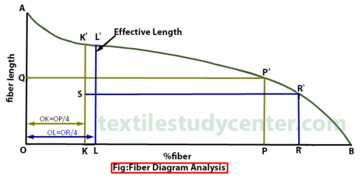

Effective length can be determined from the analysis of fiber diagram by the following construction:

- Halve the maximum length OA at Q and determine the position of P such that the perpendicular PP’ = OQ.

- Mark off OK = OP/4 and erect a perpendicular KK’ cutting the curve at K’.

- Halve KK’ at S and determine the position of R such that the perpendicular R’R = KS.

- Mark off OL = OR/4 and erect a perpendicular LL’, cutting the curve at L’. The length represented by LL’ is the effective length.

Relation between effective length and staple length:

Lord and Underwood have reported that a simple relationship can be established between effective length and staple length for American upland cottons of 19 to 32 mm (0.75 to L25 in.) lengths. This is given by

American staple = 0.91 x effective length.

However, they reported that for Egyptian cottons the effective length corresponds reasonably close to the classer’s estimate of the staple length.

For Indian cotton,

Indian cotton staple=0.85 x effective length

Dispersion:

It represents the variation in the length of fibers. The variation can be expressed as the ‘inter-quartile range’. In Figure L’L is the upper quartile and M’M is the lower quartile, where OM = ¾ OR. The difference between L’L and M’M (NL’) is the inter-quartile range. This measure of the dispersion may now be expressed as a percentage of the effective length.

(3478)