Fabric Width and Thickness Test

Fabric Width and Thickness Test

Textile Testing :

Main steps for textile testing :

- Checking raw materials

- Monitoring production

- Assessing the final product

- Investigation of faulty material

- Product development and research

Different fabric tests :

- Dimensional Characteristics – A) Length, B) Width, C) Thickness

- Threads/Inch – EPI, PPI, CPI, WPI

- Count- Warp & Weft

- Weight

- Crimp%,

- Strength

- Shrinkage

- Abrasion & Pilling,

- Handle a) Stiffness, b) Drape, c) Crease Resistance & crease recovery,

- Flame Retardancy,

- Water repellency

Fabric Length :

Fabric length is the distance from end to end, along the selvedge of a fabric.

ISI suggested the following 3 methods to measure the length of a fabric-

- By using a measuring table

- By using measuring scale

- By using a measuring machine (Trumeter)

Fabric width & thickness :

Collection of samples from fabrics :

Samples should be collected from at least three places from fabric e.g.

- two samples from the two sides and

- one from the middle.

Conditioning of test samples (Standard Atmospheric Condition) :

It is recommended that the fabric should be conditioned in the standard testing atmosphere

- 65+-2%RH

- 20+-2oC ( or 27+-2oC for tropical countries ) temperature in a fully relaxed state.

Fabric width :

Fabric width is the distance from one selvedge to the other, measured perpendicular to the length of the fabric.

Measurement of fabric width :

- In the standard method, (B.S. Hand book) it is recommended that the fabric should be exposed to a standard atmosphere for at least 24 hours before final width measurements are taken.

- Measurements should take before and after conditioning. Then it should be watched that if there is any change in width.

- On a piece of cloth, 10 width measurements should be made at points distributed at roughly equal distances throughout the full length of the fabric piece.

- If full length is not used a sample length not less than 1 yard should be used and width measurement should be taken at least 3 places.

- Then, in both cases, mean width should be calculated.

Continuous measurement of width :

An apparatus is described by Jiewertz based upon a pair of photo electric cells, one at each selvedge, which scan the edges and detect changes in width. The signals are translated into cloth width and indicated on a meter or recorded on a chart. An accuracy of +-0.3 cm is claimed.

Fabric thickness :

Thickness is a parameter of a fabric which controls handle, creasing, thermal resistance, heaviness or stiffness in use and many other properties of fabric.

Fabric thickness test principle :

The Principle of the measurement of fabric thickness is expressed in B.S. Hand book as follows.

“Essentially, the determination of the thickness of a compressible material such as a textile fabric consists of the precise measurement of the distance between two plane parallel plates when they are separated by the cloth, a known arbitrary pressure between the plates are applied and maintained. It is convenient to regard one of the plates as the pressure foot and the other as the anvil.”

Points to be considered in measuring thickness:

- The shape and size of pressure foot:A circular foot of diameter inch is usually used. The ratio of foot diameter and cloth thickness should not be less than 5: 1.

- Shape and size of Anvil:If a circular anvil is used it should be at least 2 inch greater in diameter than the pressure foot. Where the sample is larger than the anvil, the anvil should be surrounded with a suitable support .e.g. a smooth plane board.

- Applied pressure: Recommended pressure is specified e.g. 0.1 lb/inch2 or 10.0 lb /inch2. Suitable weights may be added to pressure foot to obtain these pressures.

- Velocity of pressure foot: The pressure foot should be lowered slowly on sample i.e. it needs slow and careful movement.

- Time: The thickness is read from the dial of the instrument when the movement of pointer has stopped.

- Indication of thickness: A clock type dial is usually built into a thickness tester.

Instruments for measuring fabric thickness :

- Reynolds and Branson thickness tester.

- Heal’s thickness gauge.

- Shirley thickness gauge.

- Mag Ana thickness tester

Shirley thickness gauge :

For testing the thickness of compressible materials like carpets, sponge rubber, foam, felts etc., Shirley thickness gauge is used.

Description of Shirley thickness gauge :

- Range of measurement: 0-2’’

- Least count of dial gauge: 0.001’’

- Area of pressure foot: 10 inch2, 1inch2 4.

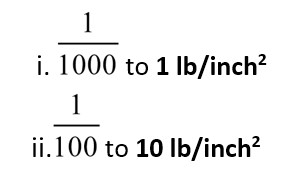

- Load on the pressure foot:

Mag Ana thickness tester :

This instrument is suitable for most of fabrics like woven fabric, knitted and layered fabric, pile fabric, unsized, heavily sized fabric, coated fabric and resin treated fabric.

Parts of Mag Ana thickness tester :

- Pressure weight

- Weight pan

- Indicator

- Lifter to place the sample piece

- Dial to indicate thickness

- Support column

- Pressure foot

- Testing base

- Base

- Rubber bush to place on the table

Specifications of Mag Ana thickness tester :

- Range of measurement: 0.01-10 mm

- Least count of dial gauge: 0.01 mm

- Diameter of anvil: 56 mm

- Diameter of pressure foot: 25 mm, 10 mm

- Load on the pressure foot: i. 78.5 gm. weight

ii.68.7 gm. weight

Procedure of Mag Ana thickness tester :

- The specimen should be conditioned at standard atmospheric condition.

- The pressure foot is lifted with the help of the lifting lever.

- The specimen is placed on the anvil just below the pressure foot and the pressure foot is gently lowered on to the specimen.

- The reading of the dial gauge is noted to get the thickness of the specimen at normal load.

- Then, the weights are placed in the top pan of the tester in an increasing order and readings are noted.

- The above procedure is repeated for at least five locations to obtain the value of thickness of randomly distributed location over the whole of the sample.

- Selvedges, wrinkles, folds, knots, missing ends, missing picks, float, starting marks, irregularity and some of visible defects should be avoided.

- The mean value of all the readings of thickness is calculated and the average thickness of the sample is reported.

(6754)