Directional Field Effect in Wool fiber | Significance of DFE | What is DFE

DFE (Directional Field Effect) in wool fiber

What is DFE ?

We all know that, textile fibers have to undergo various processes before they become a part of the fabric. While undergoing these processes, the fibers are subjected to friction. This frictional force can not only be effective between the fibres & various parts of the machine, but also between the fibres themselves.

Wool fibres are not exceptional to this phenomena. But the thing unique about wool fibres is that, due to its unique morphological structure, the friction in wool fiber depends on the direction in which it is pulled. The frictional force/resistance is greater when it is pulled against the scales than when it is pulled with them. This phenomena is known as the “Directional Field Effect” (DFE).

Various forms/combinations of DFE

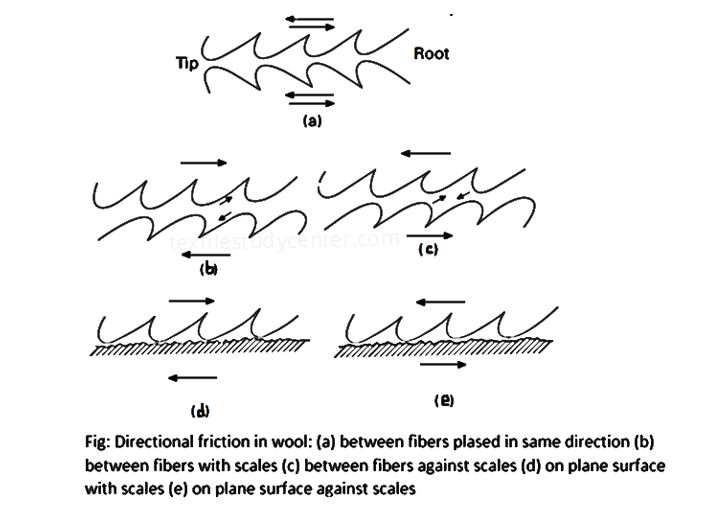

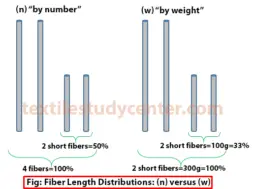

The various forms/combinations of DFE, that can occur in wool fibers can be illustrated in the figure below :

Reasons behind DFE

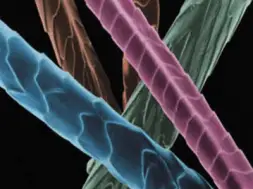

The wool fiber has a unique morpholgical structure. In longitudinal microscopic appearance of its surface, it can be seen that it has overlapping surface cell structure. These surface cells are called epithelial cells (commonly known as scales). These scales, pointing towards the tip of the fibers, make up a scaly fiber surface.

When wool fibers are pulled against the scales on each other’s surfaces (figure 25.26(b)), or, on a plane surface against the scales (figure 25.26(d)); the scales interlock with one another, or, catch against asperities on another’s surface respectively. For this, motion against the scales would be strongly resisted. Because it can cause rupture or deformation of the scales, if motion is continued.

On the contrary, When wool fibers are pulled with the scales on each other’s surfaces (figure 25.26(c)), or, on a plane surface with the scales (figure 25.26(e)); the scales do not interlock with one another, or, catch against asperities on another’s surface respectively. That is why motion is less resisted and there is less friction between the fibers.

Consequences/Influences/Significance of DFE

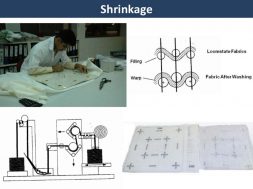

The DFE in wool fibres has important techincal consequences/significances. DFE in wool fiber suggests that, in a mass of wool, individual fibres will show preferential movement in one direction and will continuously entangle themselves with the remaining fibres. This tendency leads to the irreversible shrinkage property of wool fibres. This phenomena is commonly known as felting of wool fiber.

Variation in DFE

It has been shown that the effect persists (though to a reduced extent), when the fibres are lubricated or coated with thin films of gold or silver. In water, or other swelling agents, the difference in the co-efficient of friction (or, frictional resistance, i.e. DFE in this case) is greater than it is in air.

On the other hand, the difference is less after mechanical abrasion or chemical treatments. That is why, these treatments are used to reduce shrinkage, which attack the outer layer of the wool fibre.

DFE (Directional Field Effect) in wool fiber

(1926)