Index of Irregularity

Limit Irregularity and Index of Irregularity

Yarn Evenness-1 Yarn Evenness-2 Yarn Evenness-3

Limit Irregularity

For a particular fiber and count of yarn, there is a basic or limit irregularity which cannot be improved by the spinning machinery. The CV of the most regular/uniform strand of material in which the fiber ends are laid in a random order in the sliver, roving, or yarn is called limit irregularity. The basic irregularity is given by the following equation

Math:

Index of Irregularity

The ratio between the actual irregularity present in the material and the calculated limit irregularity is called index of irregularity. It is denoted by I. Accordingly the best yarn have a value of I = 1. Thus, the higher value of I indicate that the yarn is more irregular.

Addition and Reduction of Irregularities

Addition of Irregularities

Generally, each machine in the spinning process adds a certain amount to the irregularity of finished yarn. This is mainly due to the deterioration effect of the drafting process. The resultant irregularity at the output of any spinning process stage is equal to the square root of the sum of the squares of the irregularity of the input material and the irregularity introduced in the process.

Mathematically stated, if CVout, is the CV (%) of output material, CVip is the CV (%) of input material, and CVad is the irregularity introduced/added by the machine, then the relation is given by as follow,

The relationship between the irregularities may be graphically represented as in Fig.

Math:

A blend yarn manufactured according to the cotton spinning process contains 45% cotton and 55% synthetic staple materials and has a yarn count of 33.3 tex. The fiber fineness for the synthetic 0.44 tex and the cotton diameter is 0.224 tex. Find out the limiting irregularity of the blended yarn?

Reduction of irregularity by doubling

One of the objects of doubling is to reduce the irregularity. If n strands of material, each having the same coeflicient of variation, are doubled, then the coeflicicnt of variation of the combined strand is given by

Thus, by doubling two rovings, the coefiicient of variation is divided by √2.

Math:

A drawframe is fed with 8 cotton slivers 4 ktex of mean CV=2.8%.If irregularities of doubled sliver be 2.5%, how large the irregularities will be added by the drawframe?

Math:

A draw frame is going to be fed with n cotton slivers of 0.12 Ne and 2.8% mean CV. Find the required numbers of slivers (n) to maintain 2.5% CV in output sliver. Let the machine adds 2.3% CV due to drafting operation.

Irregularity of Ply Yarn

If yarns with the same unevenness (CVc) are twisted together, then the random variations of unevenness of ply yarn (CVp) will be,

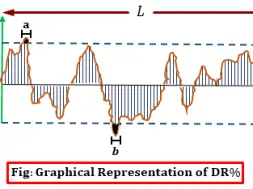

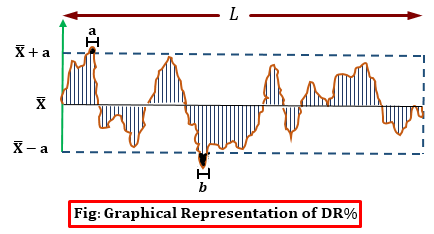

Deviation Rate

Deviation rate describes by what percentage a mass deviation exceeds or falls below a certain limit. The values of the deviation rate both on the positive and negative side can be obtained at the selected value of level and reference length. The DR% is represented in Figure. In this example, samples a and b, exceed the defined threshold (sample a by excess and sample b by shortage). As there are two samples outside the limits, the deviation rate per length of sample is (2 Lsample/N) x 100%, where N is the number of samples acquired.

Relative Count

The relative count describes the variation in count of fiber assemblies between separate measurements within a sample. It is always estimated with reference to a test length of 100m or 100 yards.

Relative count 1.5% means the count is 1.5% coarser from mean i.e if the mean count considered as 100 Ne than the actual count will be 101.5 Ne.

Relative count -0.5% means the count is -0.5 finer from mean i.e if the mean count considered as 100 Ne than the actual count will be 99.5 Ne.

(4582)