Drawing Of Synthetic Fibres

Drawing Of Synthetic Fibres

Introduction:

- With the exception of silk , all the filaments are manufactured from man-made materials . silk is a natural filament.

- The man-made materials are primarily made from chemicals that must be formed and solidified into fibre form.

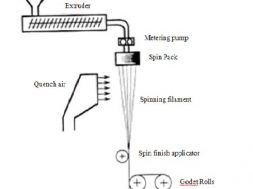

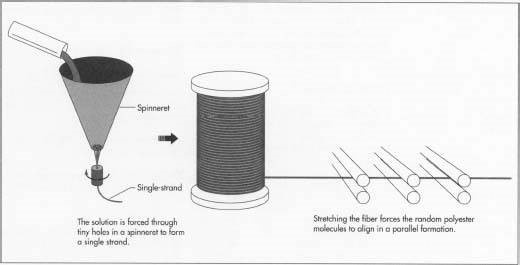

- The fibre forming polymers are normally solids and therefore must be first converted into a liquid form to be suitable for extrusion.

Drawing:

- Drawing is very important process of spinning.

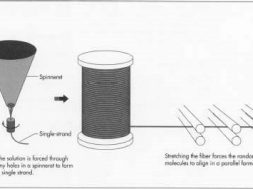

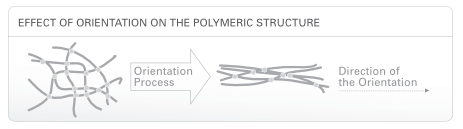

- This process used to increase the orientation of polymer molecules.

- It produce filament with desired strength.

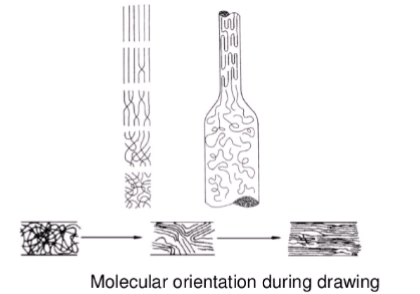

- During the drawing operation molecular chains are aligned along the fibre axis.

Undrawn fibre properties:

- Semi-crystalline

- Lamellar structure

- Amourphous region

- Low rigidity and strength but high elongation

Crystalline and strength:

- Drawing process increases tensile strength and hardness of filament.

- It orients the polymer molecules along the filament.

- Crystallinity increases due to the orientation of polymer molecules.

Properties induced by drawing:

- High degree of orientation of polymer molecules that tends to increase fibre stiffness.

- More breaking strength.

- Low moisture absorption.

- More luster and transparency.

- Fibrillar structure.

- More dimensional stability.

Objective of drawing:

- To induce the molecular orientation in the fibre.

- Thereby increasing their strength in the direction of stretch.

- Extension of the filaments to many times their original length.

Purpose of drawing:

The primary purpose of drawing of yarn is to be a desirable quality for the following reasons :

- To increase the crystalline zone in fibres.

- To produce fibres with the specific properties desired.

- To convert relatively week spun fibres to fibres with greater molecular orientation and the resulting greater strength.

- To produce filaments with a desired strength by inducing sufficient orientation of the polymer molecules along the axial direction.

Draw ratio:

The ratio between the take-up roller and the extrusion rate is known as draw ratio.

If we increase the take-up speed draw ratio will be increase.that means fibres will be stretched according to our requirement.

Types :

- Low oriented yarn(LOY)

- Partially oriented yarn(POY)

- Fully oriented yarn(FOY)

LOY : There is no orientation as well as crystallinity.

POY: There is a orientation without crystallinity.

FOY: There is a orientation with crystallinity.

|

Type |

Spinning speed |

|

LOY |

500-1500 MPM |

|

POY |

1500-4000 MPM |

|

FOY |

4000-6000 MPM |

Principle of drawing :

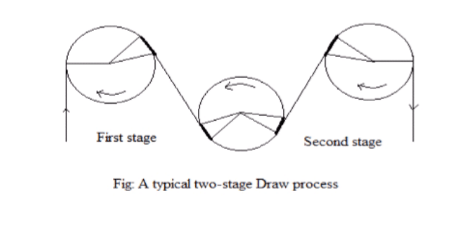

- The drawing process of the fibre involves passing the fibre tow over a series of rollers.

- The roller rotates at specified constant angular velocities,each faster than older.

- In some processes all the draw is introduced in one step,in a single stage of feed and take-up rollers.

This single draw can results in fibre breakage so it customary to involve more draw processes in the industries.

Two stage drawing process :

- In this process most of the draw was provided in the first stage ( between 2.2 and 2.7 draw ratio) and relatively smaller draw (1.1 – 1.2) in the second stage.

- As the number of stages is increased , it is possible to keep each free span and roller at a different temperature .

It induce maximum molecular orientation in the fibre.

Impact of drawing :

Fibres change in appearance as they are drawn

Example :

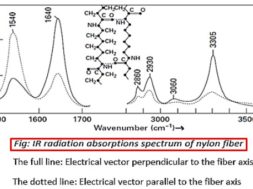

Nylon is usually dull and opaque , but after the drawing it will be transparency and luster.

- The more closely the molecules pack together , it has greater ultimate strength.

- Due to the increase of ultimate strength decrease in elongation before reaching it breaking point.

- More stiffness and rigidity because of molecules are packed compactly , so that resistance of movement.

- More resistance to penetration by the foreign molecules also improves resistant to chemical attack.

Errors in drawing :

There is a number of drafting stages , the results are cumulative and the range of error wavelengths can be very large.

The biggest advantage of POY :

POY are used in texturising process.

For a texturising operation POY is better than FOY. Why ?

We know that texturising is the thermo mechanical process.if we need to texturise the FOY

- Soft the material

- Then bring the form and set it.

FOY will be soft in melting point , also we have decrystallize the FOY because FOY contains more crystallization regions.

But in the POY no need for decrystallize , directly bring the form and set it . so that POY is better for texturising process.

(3209)