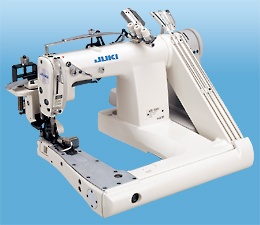

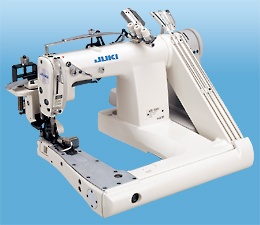

Feed of the Arm Sewing Machine II Study on industrial feed of the arm sewing machine with thread path diagram

Experiment Name : Study on industrial feed of the arm sewing machine with thread path diagram.

Introduction :

The machine which practices stitches by the loop of one group of thread links with the loop of other group of thread by the process of interloping is called the industrial feed of the arm machine.

There are two types of thread one is called “needle thread” and another one is called “looper thread” both of two this comes from large package of cone and stitch is formed by interloping technique.

As both thread comes from cone package so there is no problem for thread storage in the time of stitching.

By this machine multithread chain stitch can be produced on garments.

This machine is frequently used in stitching on heavy fabrics like denim or jeans.

It has opportunity of stitching by folding the fabrics. Different sizes of needle can be used in this machine depending on thickness of fabrics.

Objectives:

- To know about the feed of the arm machine.

- To know about the different parts of this machine.

- To know about the tread path

- To know about the specification of this machine.

- To know about the working principle of the machine

Machine Specification of feed of the arm sewing machine :

|

M/c Name |

Industrial feed of the arm machine |

|

Brand Name |

Different (Juki) |

|

Model no |

Different (MS-1190M) |

|

Origin |

Japan |

|

Group |

Multi-thread chain stitch |

|

Needle Name |

UY X 128 GAS |

|

Needle Size |

9,11,14,16,18,20,21 |

|

SPM |

6000

|

|

TPI |

8 inch/12 inch |

|

No. of Needle |

2/3 |

|

No of Thread |

4/6 |

|

No of Looper |

2/3 |

|

Bobbin case No |

X |

|

Intralooping |

X |

|

Interlooping |

Interlooping |

|

Seam Class |

Lapped |

|

Stitch Class |

400 |

|

Remarks |

Lapped seam making |

Main Parts of feed of the arm sewing machine:

1: Thread stand

- Cone case

- Thread guide

- Spring tensioner post box

- Thread take-up lever

- Needle

- Needle bar

- Folder (lapped)

- Feed dog

Throat plate

Looper

- Presser foot bar

- Presser foot

- Needle plate throat plate

- Stitch density regulator

- Presser foot lever

- Motor

Functions of different patrs of feed of the arm sewing machine :

|

Cone |

Helps for containing supply of needle thread. |

|

Cone Holder |

Supports the cone. |

|

Cone Stand |

Helps to support the cone and holder. |

|

Tensioner |

To control proper tension on sewing thread. |

|

Thread guide |

To control the thread path and support the sewing thread. |

|

Needle |

Needle carries needle thread and helps in penetration and helps in sewing |

|

Feed dog |

To move the fabric along by a pre-determined amount between successive stitches. |

|

Pressure foot

|

To control the movement of fabric by keeping proper pressure. |

|

Folder |

It is a special parts of the feed of the arm machine. By using folder lapped seam can be formed automatically during sewing. |

|

Motor |

Motor rpm controls the speed of the machine. The rpm is controlled by the tightening or losing the belt over machine and motor pulley. |

Working Principle of Feed of the Arm Sewing Machine:

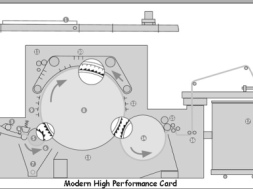

For the formation of multithread chain stitch, two threads that means one needle reaches to its lowest bottom designation entering into the fabric with “needle thread”. Then it stays a little upper. As a result a loop of needle thread is formed. At the sometimes the thread take-up lever also continuous to go downwards resulting the decreasing of the tension of the needle thread and it helps in formation of the loop of the needle thread. Just the moment of formation of the needle thread loop, the looper from behind the needle enters into the just produced needle thread loop with looper thread and goes formed a little. Then, the needle goes upward with needle tread, the fabric also goes forward a step with the help of feed dog and the looper comes in front of the needle. The movement of the looper is controlled by avoiding motion. The tension of looper thread is controlled by changing the passage of thread.

Stitch Description:

Stitch Class-400, Multi-tread chain stitch group of stitch is chain stitch. In this machine, there are two types of thread one is called “needle thread” and another one is called “looper thread” both of two this comes from large package of cone and stitch is formed by interloping technique.

Uses of Industrial Feed of the Arm Machine:

- For making garments of jeans fabric

- Used in long seam of trousers

- Frequently used for joining lace

- Used for joining braid and elastic in the garments.

Conclusion:

By this experiment, we have learnt about different parts of a feed of the arm machine, its function, working principle and use. Special care and sufficient knowledge is necessary for proper working of sewing machine. Otherwise faulty sewing may be created. It would like to give special thanks to teacher and instructor as this will be helpful in our future life.

(5248)