Polysaccharide Thickeners

Polysaccharide Thickeners

Introduction:

Thickener is a colorless thick mass which imparts stickiness and plasticity to the print paste so that it may be applied on the fabric surface without bleeding or spreading and be capable of maintaining the design out lines.

Polysaccharides:

Nature has provided large quantities of many polymers that are soluble or dispersible in water to give viscous pastes.Each plant species synthesizes one or more polysaccharides from the constituent sugars, and some plants (potatoes, for example) produce them in purity and in quantities that make extraction very simple.

Features of polysaccharides:

- may be homopolymers, composed entirely of one sugar unit, or

- heteropolysaccharides with two or more hexose or pentose units assembled in arelatively ordered sequence

- polar side-groups may all be hydroxyls, as in starch,cellulose and guar gum, or

- may include carboxyl groups as well, as in alginate and gum arabic

- Less frequently, other water-soluble groups are found

- degree of chain branching affects the solubility, film and viscosity properties

The sources of useful polysaccharides:

1.plant seeds which contain starch or similar products as a food reserve and may be cultivated for industrial use (such as guar)

2.seaweed, the only source of alginate

3.plant gum exudates, of which the best known are gum arabic and gum tragacanth

4.the cultivation of selected micro-organisms, carried out under controlled conditions, converting waste carbohydrate into useful polymers (such as xanthan)

5.cellulose pulps, from which cellulose ethers are produced

Here, I am discussing 12 types of polysaccharide thickener.

- Starch and its derivatives

- British gums

- Locust bean gum

- Guar gum

- Starch & Cellulose ether

- Alginate

- Gum Tragacanth

- Gum Arabic

- Viscose Emulsion

- Synthetic Polymer thickener

- Viscose Foam

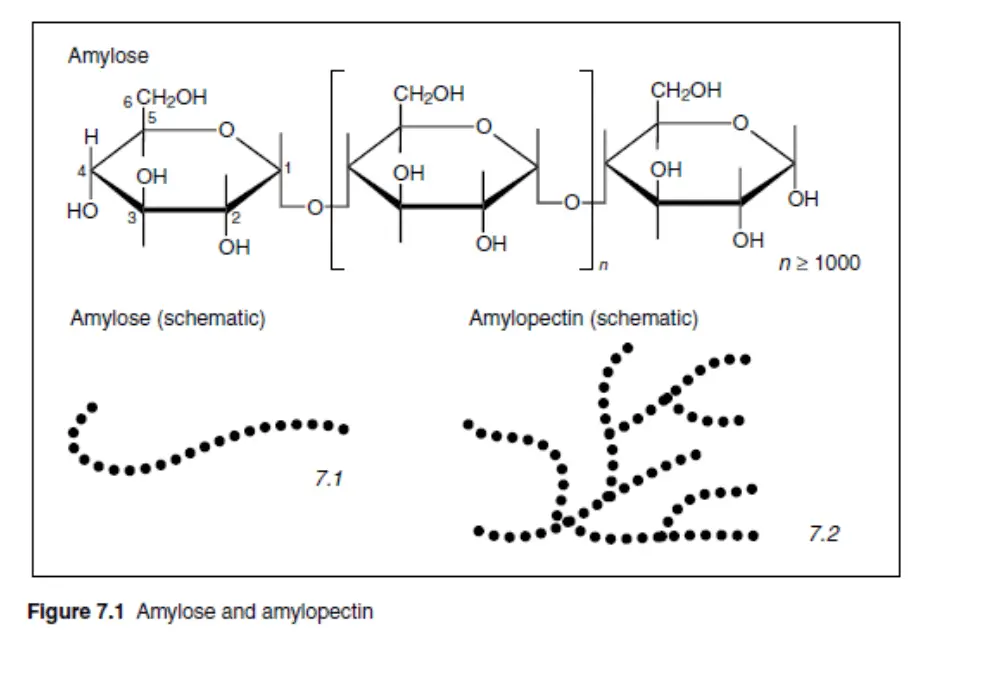

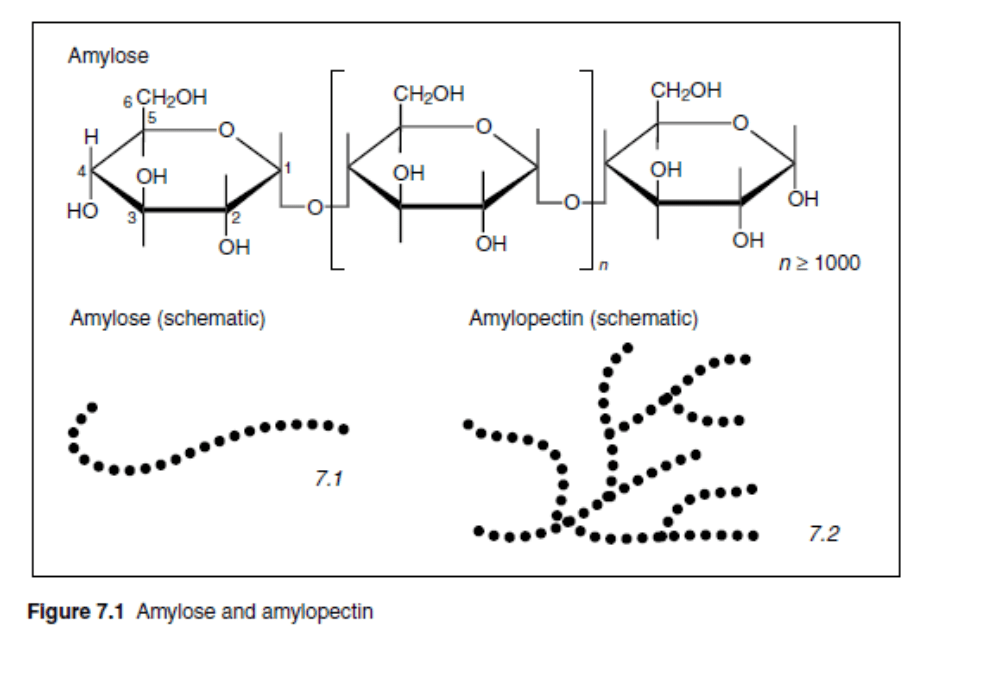

Starch and its derivatives:

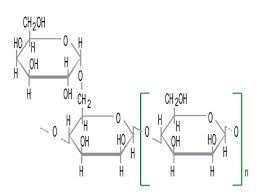

1.a homopolymer of glucose (D-glucopyranosyl) units, with most of the units joined by ?-D(1→4) linkages.

2.the most abundant of the plant products and has therefore provided a readily available and low-cost source of industrial materials

3.used in textile print pastes, but are less important than they were because of the increased availability of technically superior materials, some of which are starch-based

Structure:

Physical characteristics:

- found in a strongly aggregated state, organized in granules around crystallization nuclei

- granules of each type of starch (rice, potato, wheat and so on) have a characteristic structure which is readily identifiable under the microscope

- necessary to break down the granules, by boiling or by grinding and dispersion in hot water, to obtain smooth, viscous pastes

- If such a paste is dried rapidly, cold-water-dispersible starches are obtained, but

- slow drying allows substantial reaggregation and crystallization to occur and the product is no longer dispersible in cold water

- pastes containing amylose, as mentioned above, are not stable and may form gels and precipitates of amylose aggregates

Suitability of use:

- It gives high colour yields as a result of its aggregation and very limited penetration into textile yarns and therefore the retention of dye on the fabric surface.

- However, it is usually desirable to reach a compromise between high colour yield, with substantial susceptibility to crush and poor levelness, on the one hand, and low colour yield with good penetration, little crushing and good levelness,on the other.

- A traditional method of achieving such a compromise was to use a mixture of starch and gum tragacanth.

British gums:

An alternative approach to improving the properties of starch has been to bring about structural changes by simple roasting processes

originally produced by heating batches of dry starch at 135–190 °C, with stirring to achieve uniform roasting, for 10–24 h.

The process can be accelerated by addition of trace quantities of acid, and can then be carried out continuously on a conveyor belt

The use of more than trace quantities of acid leads to more hydrolysis and the formation of the so-called dextrins, which are of low r.m.m. and can be used as adhesives

Features:

- water soluble, reduced r.m.m., more highly branched molecules, and

- some increase in the content of reducing end-groups

- A range of products, pale to dark brown in color, requiring increasing concentrations for a given paste viscosity, can be blended to give the required properties

Suitability of use:

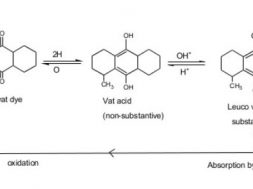

- Have good stability to alkali and have been used for printing vat dyes

- For reducible azo dyes, additions of oxidizing agent must be made to avoid destruction of dye

- In resist printing, when a high-solids-content thickener is desirable to act as a physical barrier

Locust bean gum:

Locust bean gum, often referred as LGB, is a galactomannan vegetable gum extracted from the seeds of the carob tree. It is also known as carubin, gatto, tragon, tragasol.

Origin: Carob bean

Structure:

It is a linear polymer of (1-4)-linked β-D-mannose units with about every fourth unit carrying an α-D-galactose unit on its carbon number 6.

Composition:

Beans consist of pulp = 90%

kernels (seed) = 7%

Kemel consists of husk = 30%

gem = 25%

endosperm = 45%

Commercial gum contains 88% of D-galactomannoglycan with small amount of other carbohydrates and protein.

Carob bean

Characteristic feature:

- Nonionic polysaccharide.

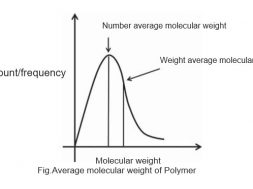

- Typical relative molecular mass = 300000

- Viscosity of an LBG thickened solution increases as temperature decreases.

- Appearance: Cloudy, though modified versions of LBG can be transparent.

- Disperse in cold water

- Addition of sodium salts has little effect on paste viscosity, but complexes are formed with borates and produce gel. This gel has been exploited in the two stage fixation of vat prints.

- Flavor release : Good

- pH has little effect on the viscosity over the pH range 3-11

- Give smooth, thick and creamy mouth-feel

- A strong & rigid gel forms when combine with xanthan, which can be firm and elastic at higher loading levels

- Really shines when used with other ingredients to prevent syneresis or improve gel texture.

- Etherification has been used to produce readily disperse material.

Concentration range:

- Use between 0.1% to 1% LBG for most application

- To thicken most liquid, use 0.1% LBG

- To prevent syneresis in agar gel, replace 0.1%-0.2% with LBG

- As ice cream stabilizer, use 0.15% LBG

- To make sorbet, use 0.35% LBG

Application:

- LBG is primarily a thickener that forms viscous

- It is used to make hot fruit gels when combined with xanthan gum

- LBG works really well in ice-cream that produces a smooth texture and a slimy mouth-feel.

- It is also used in soft drinks, fruit juice, pastry& instant pudding.

- Combined with agar to make tangy gel.

Fig: Structure of locast bean gum

Guar gum:

Guar gum is chemically similar to locust bean gum (It is also a galactomannan vegetable gum) and like locust bean gum is a very useful thickening agent.

Origin: The guar plant (Cyanaposistetragonolobus) is an annual leguminous plant.

Guar plant

Structure:

- Consists of D-mannose monomer units linked to each other by β-(1-4) linkage forms backbone.

- Branches of D-galactose joined by α-(1-6) bonds.

- On the average, the galactose branches occur on every other mannose unit.

Fig: Structure of guar gum

Rheology:

- Shows pseudo-plastic or “shear thinning” behavior in solution.

- The degree of pseudo-plasticity increases with concentration and molecular weight.

- Solutions of guar gum do not exhibit yield stress properties.

Characteristic Features:

- High molecular weight polymer.

- Nonionic hydrocolloid.

- Compatible with most nonionic and anionic gums.

- Soluble in salt solutions that contain up to 70% by weight of monovalent cation salts.

- Highly dispersible into cold and hot water.

- The hydration and the swelling are slower in low-temperature water.

- Thickens spontaneously without the application of heat.

- Tolerance decreases as the valency of cations increases.

- Solutions are stable between pH 4 to 11; viscosity peaks between pH 6 to 8.

- Solutions are susceptible to bacterial, heat, enzyme and UV degradation.

Application:

Guar gum is mainly used as a

- Natural thickener.

- Emulsifier.

- Stabilizer.

- Bonding agent.

- Hydrocolloid

- Gelling agent.

- Soil stabilizer.

- Natural fiber.

- Flocculants.

- Fracturing agent.

Starch & Cellulose ether

- Modified starch

- Prepared by physically,enzymatically or chemically treating native starch to change its properties

- Ethers are produced by reaction with monochloroacetic acid & epoxyethane or dimethyl sulphate in the presence of sodium hydroxide.

Characteristic feature

- A concentration of 6% gives a paste of suitable viscosity.

- Increasing solubility against excessive heat,acid,shear,cooling.

- slight reduction in r.m.m., viscosity and colour yield

- Increase visco-stability.

Application

- Used as thickening agent,stabilizer or emulsifier

- Binder in coated paper

- In pharmaceuticals as a disintegrant & excipient

- Used as a fat substitute

- Oxidizing modified starch ,used in increasing the stickiness of batter

Solubility of application

Zonnenberg has described the properties of such starch ethers as ideal in respect of colour yield and solubility.They have been recommended for use in mixtures with galactomannans or alginate, to increase colour yield.

Alginate

Alginate are hydrocolloids,water soluble biopolymer and mostly it is extracted from brown Phaeophycae seaweeds.First researched in the late 19th century by british chemist E.C. Stanford although it was another 50 years to produce it commercially

(2187)