Basic weft Knitting Loops

Basic weft Knitting Loops (Formation, properties and effects)

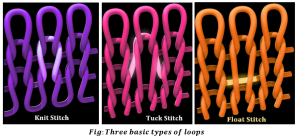

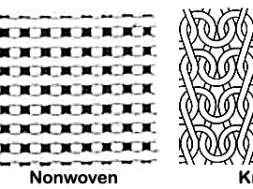

There are three basic types of loops of weft knitting

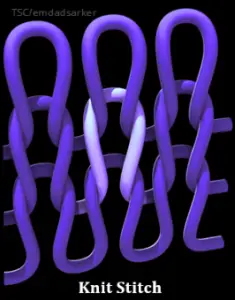

Features of Knit stitch

When the needle is raised sufficiently high by the camming action to obtain the yarn in the hooked portion of the needle and the old loop is below the latch [i.e, the old loop is cleared], a knit stitch will be formed as the needle descends.

A knitted loop stitch is produced when a needle receives a new loop and knocks over the old loop that it held from the previous knitting cycle.

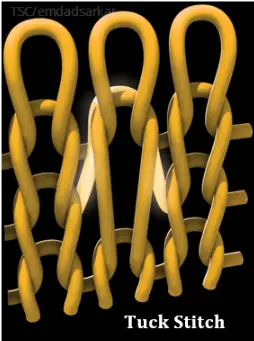

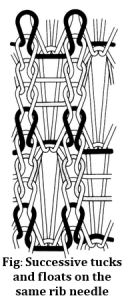

Tuck Stitch

Features of tuck stitch

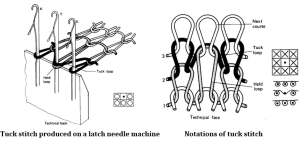

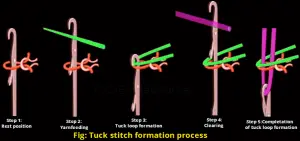

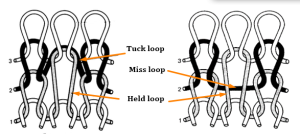

A tuck stitch is composed of a held loop, one or more tuck loops and knitted loops.

It is produced when a needle holding its loop (T) also receives the new loop, which becomes a tuck loop because it is not intermeshed through the old loop.

The tuck loop thus assumes an inverted V or U-shaped configuration.

The head of the tuck is visible on the reverse of the stitch.

The side limbs of tuck loops thus tend to show through onto the face between adjacent wales.

Tuck stitch structures show a faint diagonal line effect on their surface.

In analysis, a tuck stitch is identified by the fact that its head is released as a hump shape immediately the needle loop above it is withdrawn.

A knitted loop would be required to be separately withdrawn.

Effect of tuck stitches

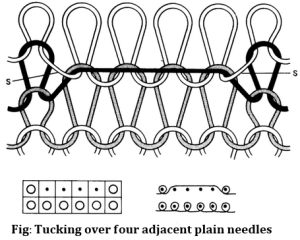

Fabric with tuck stitches is thicker than knit stitches due to accumulation of yarn in stitches at tucking places.

The structure with tuck stitches is wider than with knit stitches as the loop shape has a wider base.

As the loop length is shortened, the tuck https://eteh.com.ua stitched structure is less extensible.

Due to thicker in nature, the tuck stitched fabric is heavier in weight per unit area than the knit stitches.

Tuck stitched structure is more porous and open than the knit stitched fabric.

Tuck stitch is also used to get fancy effects by using colored yarns.

Tuck loops reduce fabric length and length-wise elasticity because the higher yarn tension on the tuck and held loops causes them to rob yarn from adjacent knitted loops.

Fabric width is increased because tuck loops pull the held loops downwards, causing them to spread outwards and make extra yarn available for width-wise extensibility.

Fabric distortion and three-dimensional relief is caused by tuck stitch accumulation, displacement of wales, and by varying numbers of tuck and knitted stitches per wale.

The tuck stitch may also be employed to produce open-work effects, improve the surface texture, enable stitch-shaping, reinforce, join double-faced fabrics, improve ladder-resistance and produce mock fashion marks.

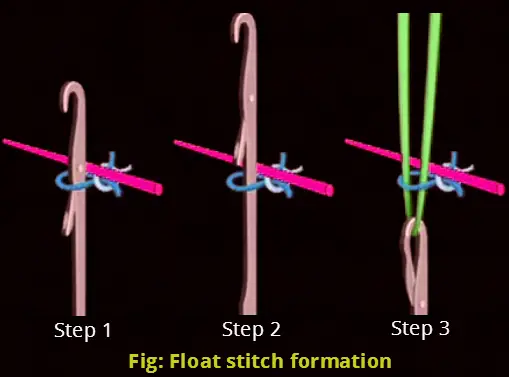

Float or missed stitch

Features of float stitch

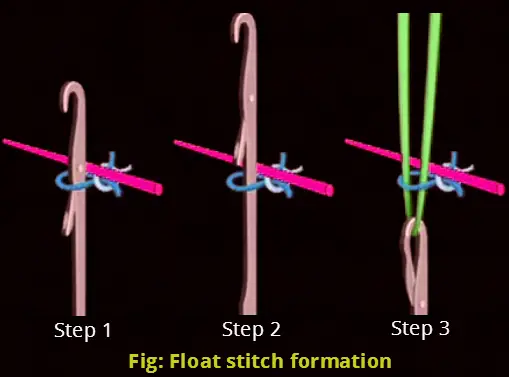

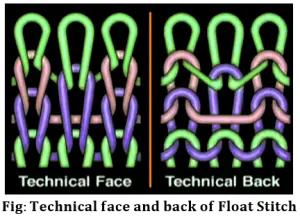

A float stitch or welt stitch is composed of a held loop, one or more float loops and knitted loops.

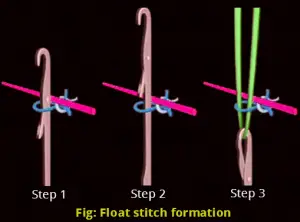

It is produced when a needle (M) holding its old loop fails to receive the new yarn that passes, as a float loop to the back of the needle.

The float stitch shows the missed yarn floating freely on the reverse side of the held loop.

The float extends from the base of one knitted or tucked loop to the next, and is notated by an empty square.

The held loop extends into the courses above until a knitted loop is indicated in that wale.

A single float stitch has the appearance of a U-shape on the reverse of the stitch.

Float stitch fabrics are narrower than equivalent all-knit fabrics.

As the wales are drawn closer together by the floats, thus reducing width-wise elasticity and improving fabric stability.

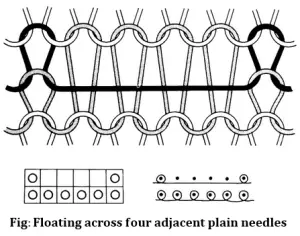

The maximum number of successive floats on one needle is four.

Six adjacent needles are usually the maximum number for a continuous float.

A floating thread is useful for hiding an unwanted colored yarn behind the face loop of a selected color.

The miss stitch can occur accidentally as a fault due to incorrectly set yarn feeders.

Float Stitch Formation Process

Effect of float stitches

Float stitches make the fabric thinner than the tuck stitched one, as there is no yarn accumulation.

It makes the fabric narrower as there is no looped configuration and hence the whole structure is pulled to minimum width.

Less extensible than either knitted or tucked structure.

Fabric is lighter in weight due to minimum yarn used in construction.

Fabric is flimsy and less rigid compared to others.

Held loop

A held loop is an old loop that the needle has retained.

It is not released and knocked-over until the next, or a later, yarn feed.

A held loop can only be retained by a needle for a limited number of knitting cycles before it is cast-off.

A new loop is then drawn through it, otherwise the tension on the yarn in the held loop becomes excessive even though there is a tendency to rob yarn from adjacent loops in the same course.

The limbs of the held loop are often elongated. They extend from its base, intermeshing in one course, to where its head is finally intermeshed.

A held loop may be incorporated into a held stitch without the production of tuck or miss stitches in either single- or double-faced structures.

In single-faced structures, it can only be produced on machines whose feeds or needles have a reciprocating action so that the yarn only passes across needles that are knitting, otherwise a float stitch would be produced.

Held stitches are produced in double-faced structures by holding loops on one bed whilst continuing to knit on the other, thus producing horizontal welt and cord effects.

Held stitches of this type are used for producing three-dimensional shaping such as heel and toe pouches for footwear, held-loop shaping on flat machines, and designs in solid color intarsia.

Drop or press off stitch

A drop stitch fault will result if a needle releases its old loop without receiving a new one.

Sometimes this technique is used to achieve a press-off on all needles at the end of a garment-length sequence.

A drop stitch or press-off stitch is used very occasionally in flat knitting to cause certain loops in a plain structure to be much larger than the rest. Knitting takes place on only one bed of needles and selected needles in the other bed pick up loops that are immediately pressed-off by not receiving yarn at the next feed.

(6491)