Lap Preparation in Combing | Sliver Lap Machine | Ribbon Lap Machine

Part 1: Basic Concept of Combing Process | Types of Comber Machine

Part 2: Lap Preparation | Sliver Lap Machine | Ribbon Lap Machine

Part 3: Production Calculation of Lap Former Machine

Part 5: Production Calculation of Comber Machine

Lap Preparation in Combing | Sliver Lap Machine | Ribbon Lap Machine

Lap Preparation:

Lap preparation is the process to prepare for combing process by making flat laps with combining multiple threads of carded slivers. It is the important step in the combing process, which influences the quality of the combed sliver.

Importance of Lap Former:

To make the fiber straight and parallel in comber sliver.

To control the amount of waste.

Easy opening of fibers from sliver.

To reduce strain on combing cylinder and top comb.

To reduce fiber damage.

To reduce thick and thin place in sliver.

Importance of Pre-comb Draft:

Fiber parallelization is the result of the pre-comb draft. Greater the pre-comb draft, better fiber parallelization and less load on the cylinder as well as top comb needles. The degree of pre-comb draft has significant effect on the comber waste extracted.

Depending upon the staple length, pre-comb draft between 25 to 40 is found enough for effective fraction at the comber. Below and around 10 does not give satisfactory results and impose to much load on the needles.

Excessive pre-comb draft is also determined although it increase the degree of fiber parallelization. It develops lap licking and hampers smooth working of comber. The materials become soft and there will be excessive sliver breakage between front roller & coiler roller.

Lap preparation method

1. Conventional Method

a) Sliver lap m/c

b) Ribbon lap m/c

2. Modern Method

a) Super lap m/c

Machine Sequence:

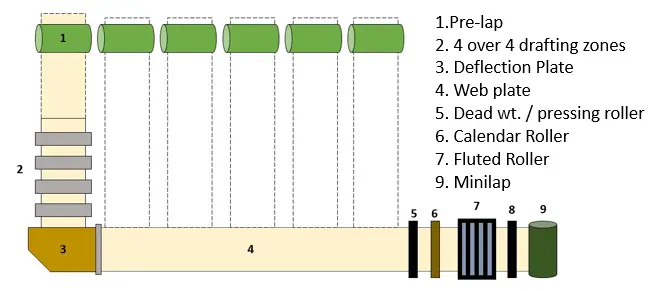

To produce a narrow lap formed sliver, to make the fiber straight and parallel by draft and finally to reduce the number of hooks in card sliver lap preparation is important. There are different methods to prepare comber lap.

Sliver lap and ribbon lap machines are used to produce the lap by doubling several numbers of slivers and webs, respectively. It is also still in use in many spinning mills. In this method, the card slivers in the range of 16–32 numbers are doubled and drafted in the sliver lap machine and the delivered lap sheet is wound onto the cylindrical spool, which is termed as “sliver lap.”

The dimension details of sliver lap are given as follows:

Lap grams per square meter (GSM) of 50–70 g/m

Width of 230–300 mm

Diameter of 500 mm

Weight of up to 27 kg

Another method has sliver doubling machine, also called super lap, used for lap preparation. It is adopted in the modern lap preparation process.

Short discussion on Ribbon lap machine and Super lap machine is given below:-

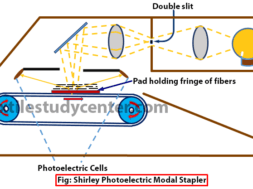

Ribbon Lap Machine:

Input: Pre-Lap

Output: Minilap

from 6 pre-lap we can get 1 minilap

Objects:

To draft the lap made on the sliver lap m/c in order to improve fiber parallelization in the lap

To improve the uniformity of lap by doubling

Fig: Ribbon lap machine

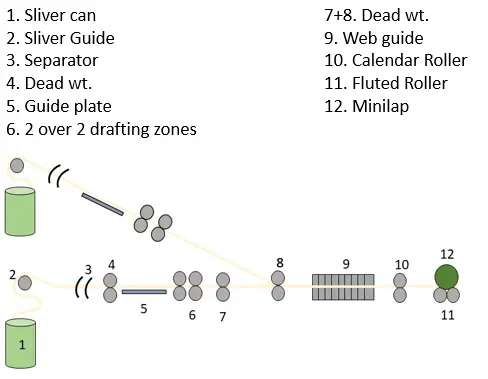

Super Lap Machine:

Input: Drawn Sliver

Output: Minilap

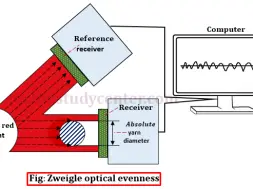

Effect of Lap Properties On Combing Performance:

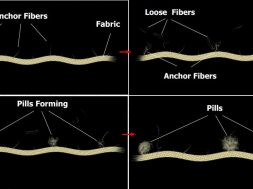

- Batt thickness: If batt thickness increases then the self-retaining effect will be increased. Then nipping will not be good and long fiber will be removed with noil.

- Batt evenness: If the batt is even in the sliver then nipping will be equal everywhere. If not then nipping will not be equal.so good or long fiber will be removed by nipping.

- Parallelization of fiber in lap: If fibers are not parallelized the good fiber will be removed

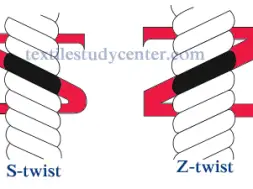

- Disposition of hooked fiber

Part 1: Basic Concept of Combing Process | Types of Comber Machine

Part 2: Lap Preparation | Sliver Lap Machine | Ribbon Lap Machine

Part 3: Production Calculation of Lap Former Machine

Part 5: Production Calculation of Comber Machine

(7739)