Modular Production System | Cellular Garment Manufacturing | Toyota Sewing System

Part 1: Garment Production System | Apparel Production System

Part 2: Progressive Bundle System

Part 3: Unit Production System | Overhead Production System | Hanger Production System

Part 4: Modular Production System | Cellular Garment Manufacturing | Toyota Sewing System

Modular Production System

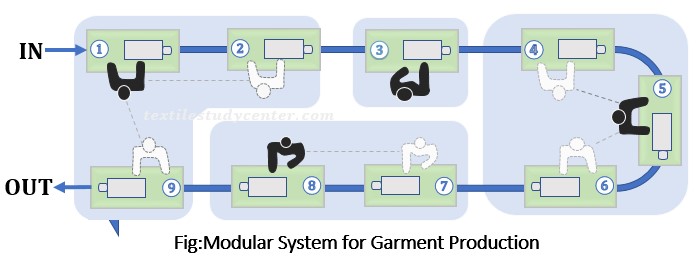

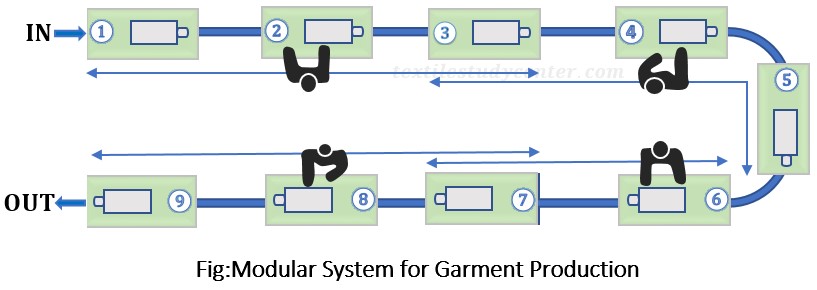

Modular production system involves a group of 4-17 people who set their own standards and work together to produce a finished garment. They work as a team or module and each team member works on more than one operation. In this system, operators help each other to finish the garment quickly and the team is fully responsible for the production and quality. The number of teams in a plant varies with the need of the industry, size of the industry and product line in garments. This system MPS is the perfect solution for the apparel manufacturer where quick response is needed. This system is also popular as a Cellular Garment Manufacturing, flexible workgroups or Toyota Sewing System (TSS).

Features of a Modular Production System

Usually U-shaped layout with more workplaces than operators.

Required multiskilled workers and a small set of machines to produce a finished garment.

Each operator performs approximately 2-4 operations, depending on the product.

Workflow is sequential.

WIP is less and productivity is high in this production system

The operators stand /sit at their stations and rotate in different sewing machines to complete the operations.

Pull-type production systems, in which the job order arrives from the last step to previous steps

Time spent per garment is also little; e.g. T-shirt 3 mins, Pull-on pants 6 mins., unstructured jacket 25 mins., lined blazer 40 mins., tailored coat 120 mins.

Advantages and Disadvantages of Modular Production System

Advantages

MPS leads to cost savings.

The system is highly flexible with style changes and permits better line balancing.

Enables fast throughput time, lower WIP, and small batch size can be achieved.

Peer pressure encourages a team spirit and discourages absenteeism.

Productivity of human labour

Reducing supplies of unfinished production

Required less floor space

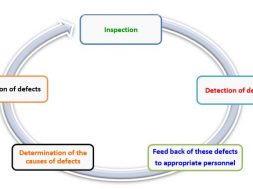

Improved quality of the product

Disadvantages

High capital investment is needed in initial training workers to deal with several tasks at one station.

This system requires a higher degree of communication and cooperation among operators, mechanics, and supervisors.

Operators cannot develop the rhythm and pace of high performance.

No harmony between team members can cause problems, thus loss in production.

Depend on the Team for whole Production.

Applications

Fashioned garments with quick response.

Orders with low volume and frequent changes.

Company with mutual trust between management and operators.

Part 1: Garment Production System | Apparel Production System

Part 2: Progressive Bundle System

Part 3: Unit Production System | Overhead Production System | Hanger Production System

Part 4: Modular Production System | Cellular Garment Manufacturing | Toyota Sewing System

(8038)