Types Of Warp Knitting Machines

8.13K

0

Types Of Warp Knitting Machines

- Warp knitting is defined as a loop forming process in which yarn is fed into knitting zone , parallel to fabric selvedge .

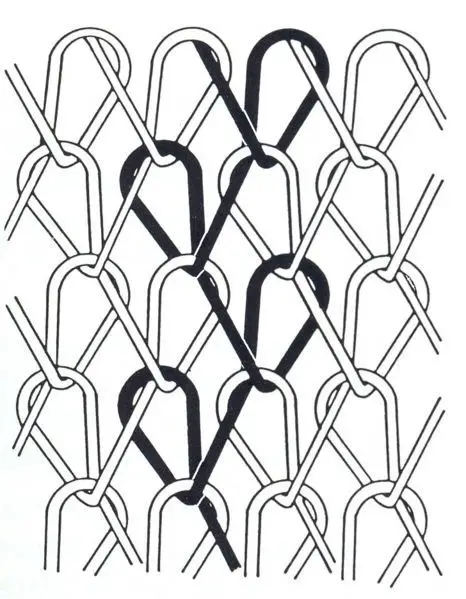

- In warp knitting , fabric is made by forming loops from yarns coming in parallel sheet form run in the direction of fabric formation . ( warp beam like in weaving )

- So that warping process is essential for warp knitting .

- Every needle is fed by a separate yarn for loop formation . In order to connect the loops into a fabric , the yarns are shifted between the needles .

- All the yarns will be knitted in course simultaneously.

- For the purpose of shifting yarn , guide will be used.

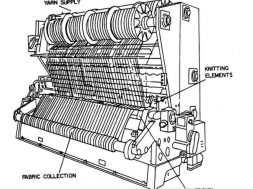

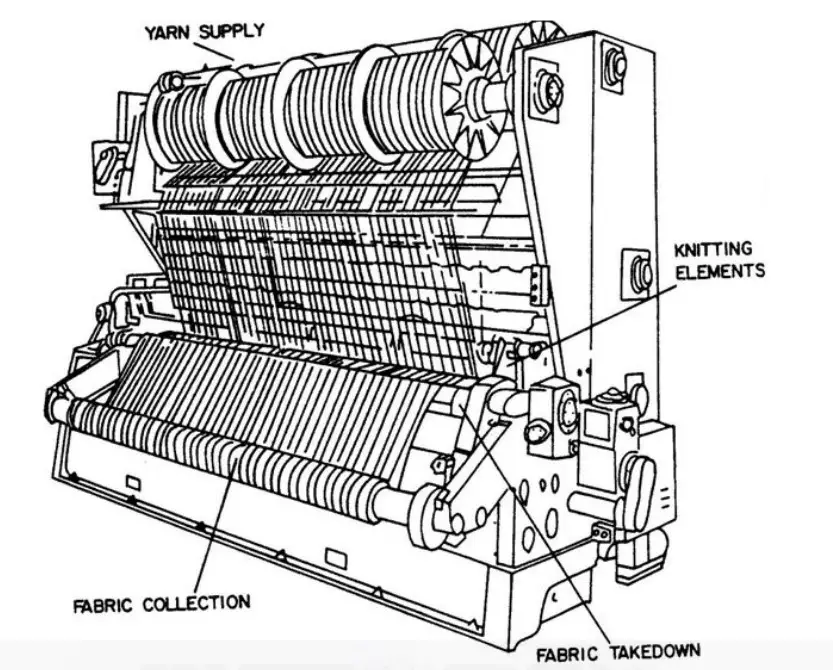

Warp knitting machines are flat and comparatively more complicated than weft knitting machines.

Types Of Warp Knitting Machines :

1 . Tricot machine

2 . Raschel machine

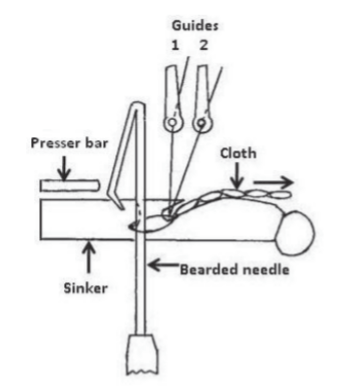

Tricot Warp Knitting Machine :

Features :

- Initially only bearded needles were used .

- Fine filaments are knitted .

- Machine gauge up to 24 to 40( here gauge is number of needles per inch)

- Fabric is pulled at right angle to needle .

- Sinker controlled fabric throughout the knitting cycle.

- Low fabric take down tension.

- Number of guide bars usually not more than four.

- Machine speed is high ( up to 3500 courses per min )

- Machines are wider and comparatively simple structures are produced .

- Warp beams are positioned at the back side of the machine .

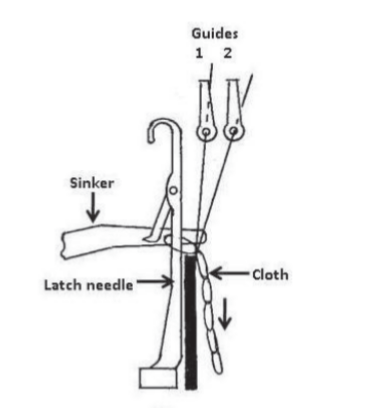

Raschel Warp Knitting Machine :

Features :

- Initially latch needles are used .

- More versatile – number of guide bars up to 16.

- Suitable for outer wear and furnishing .

- Any type of yarn can be used .

- Fabric controlled by high take down tension .

- Sinkers hold fabric only when the needles raise .

- Fabric pulled at about 160 degree to needle . machines are made in coarser gauges 24 to 64 ( here gauge is defined as number of needles per two inch )

- Machines are narrower and comparatively lower speed ( up to 2000 courses per min )

- Warp beams are positioned at the top of the machine .

Advantages :

- Due to the simultaneous knit , production rate will be much more higher than the weft knitting.

- The yarn is in criss-cross form to the adjacent wale line , so that dimensional stability will be much higher.

- Elongation of the fabric will be less.

Applications :

Warp knitted fabric will be used for apparel ,fashion fabric and technical textiles.

Apparel : Mens formal

Technical textiles : Medical textiles and auxetic textiles .

(8130)

tags:

Basic Warp Knit Structure Closed lap Fundamentals Of Warp Knitting Guide and Guide Bar GUIDE BAR MOVEMENTS Knitting Elements Knitting Terms Needles and needle bar Open lap Over lap Pressure Bar Raschel Warp Knitting Machine Raschel Warp Knitting Machine Application Raschel Warp Knitting Machine Features Shogging movement Sinker and Sinker Bar Swinging movement Tricot Warp Knitting Machine Tricot Warp Knitting Machine Application Tricot Warp Knitting Machine Features Types of chain links Types Of Warp Knitting Machines Under lap Warp Knitting